Dimensions for Detailing

Description

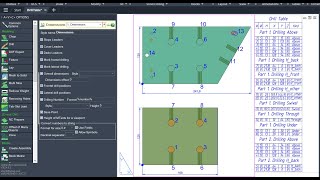

The DimDet command will help you get the details of typical flat sheet furniture items faster. The program studies the structure of selected 3D solids finds drilling holes, inclined ends, coating materials, and edge bandings, and automatically arranges leaders, diameters, blocks of hole designations, and dimensional chains. After calling this program, in many cases, you will only have to restore beauty and move the dimensions. For typical furniture parts, the program will reduce your work time to almost zero. The more complex parts will require some dimensions to be arranged manually. However, the time savings, in this case, will be huge, and the number of errors will be reduced.

Program features:

-

Analyze any 3D solids laid out in the XY plane.

-

The user can rotate the part around Z as they like. In any case, the dimensions will be placed along the X and Y axes.

-

Find drill holes suitable for CNC-style settings.

-

Create dimension chains for frontal holes.

-

Create dimension chains along the straight ends of a part up to lateral drills.

-

Take into account the priority of the 32mm step for choosing the base of the dimension chain.

-

Consider the maximum width of the drilling machine and measure from both ends of the part if the part is wider than the machine.

-

Create frontal and lateral hole diameters.

-

Use a template with hole and part property substitutions to indicate the diameter. By default, the blind hole template includes drilling depth.

-

Create conditional icons (specified blocks) instead of the hole diameter.

-

Number the drills to use the same numbers in the Drilling Table. Numbers can be displayed as Latin numbers or letters.

-

Create two overall dimensions for a part.

-

Indicate on the MLeaders the angles of inclination of the flat ends (saw blade inclination).

-

Designate the material (coating) of all visible surfaces of the part on MLeaders.

-

Designate edge materials on all ends of the part on MLeaders.

-

Using a template with substitutions, you can display any information about coatings and edge bandings, surface dimensions, edge lengths, properties of the part itself, and the drawing on leaders.

-

Mark the width and depth of dadoes and grooves on the leaders.

-

For leaders from the middle of surfaces, you can replace the arrow with a dot.

-

Place a point (_Dot block) in the lower-left corner of the part to indicate the origin of coordinates for the Drilling Table.

-

Can measure many details at once.

-

Can work in model space. All annotations will be in the XY plane of the world coordinate system.

-

Can work on sheets and measure all the details visible through the viewports.

-

When called through the viewport, the program can adapt the heights of all texts visible in the viewport (calling the Text Height Update command)

-

The program can be called together with NC Prepare and DXF Export commands.

-

You can customize which dimension and leader styles the program will use.

-

The program has several ready-made settings styles. You can create up to 9 more styles and quickly switch between them from the command line.

-

You can use layers, styles, and label blocks from the template file.

-

The program does not delete or modify the original solids in any way.

Description de l'essai

To run the plugin, you will have to register your account and top up your account balance or receive bonuses.

Then you can activate one of the licenses:

- Annual license - 15 USD.

- Unlimited license - 75 USD. Free updates for 1 year.

- The trial period is 20 days.